professional design jaw crusher

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock. They follow “crush using compression” mechanism.

More

XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone crusher

XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone crusher, crushing station, ... Tailored Professional Intelligent. ... design institutes work together for the technical communication.This will provide to clients project design, ...

More

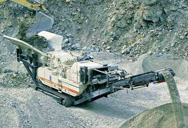

professional design jaw crusher for medium sized rock for sale

professional design jaw crusher for medium sized rock for sale for complete gravel production line. 时间/time:2018-07-24 10:14. Reliable Mini Stone Jaw Crusher For Sale From Taicheng ... 2014 professional jaw crusher, ...

More

XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone crusher

XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone crusher, crushing station, ... Tailored Professional Intelligent. ... design institutes work together for the technical communication.This will provide to clients project design, ...

More

professional jaw rock crusher design manufacture

DOVE high quality Jaw Crushers for primary, secondary and tertiary crushing, provide your crushing plant with smooth trouble-free operation and long operating life. ... DOVE Jaw Crushers are ideal rock crusher machines, ... (1,000 TPH), and compact design. DOVE 60 TPH Jaw Crusher, DOVE Factory. DOVE Jaw Crushers are supplied in large range

More

Machine Foundation Design -Stone Crusher Plant Foundations

2021年7月11日 Definitely get more info on the crusher characteristics before you proceed too much further. I am currently doing replacement supports and anchor rods to a 150 ton crusher. It is a hydraulic jaw-crusher and operates at about 3.7 Hz.

More

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

Mit Springer Professional "Wirtschaft+Technik" erhalten Sie Zugriff auf: über 102.000 Bücher; über 537 Zeitschriften; aus folgenden Fachgebieten ... Shichun, Y.: Jaw plate kinematical analysis for single toggle jaw crusher design. (2006). 10. Zurück zum Zitat Zhong, L., Chen, K.: "Study on digital design platform for jaw crusher development ...

More

PE900×1200 jaw crusher_Dingli crusher

PE 900×1200 Jaw Crusher. Introduction: The PE 900×1200 jaw crusher is a robust and efficient machine designed for primary crushing applications. It is ideal for processing hard and abrasive materials in industries such as mining, construction, and quarrying.

More

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square.

More

Jiangsu Baisheng Machinery Ltd.

Baisheng's main products include gyratory crusher, jaw crusher, cone crusher, single-stage hammer crusher, feeder, screening machine, rotary kiln, vertical mill, grinding equipment, cement production line, etc. Baisheng has the support of the most

More

Mobile Crusher Manufacturer

The product types of XC INTELLIGENT are mobile Jaw Crusher, Cone Crusher, Impact Crusher, Shock Crusher, and Screener. Product Delivered To Customer We have an efficient, safe and reliable product delivery process.

More

Jaw Crusher, Jaw Crusher Manufacturer, Jaw Crusher for Sale

Shanghai Zenith Company is a professional jaw crusher's manufacturer, provide different series and models of small and large jaw crushers. ... It is newly designed and improved by our experts on basis of their more than 20 years' crusher manufacturing and design experience.

More

The Mechanics of Crushing: Understanding the Jaw Crusher

2023年10月16日 Understanding the jaw crusher working principle can help inform operations and ... Its simple design makes it highly efficient in crushing larger rocks and boulders ... Lastly, schedule regular professional servicing. Even with daily maintenance, professional servicing is necessary. Experts can spot missed issues and offer advice on ...

More

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

Mit Springer Professional "Wirtschaft" erhalten Sie Zugriff auf: über 67.000 Bücher; über 340 Zeitschriften; aus folgenden Fachgebieten ... Shichun, Y.: Jaw plate kinematical analysis for single toggle jaw crusher design. (2006). 10. go back to reference Zhong, L., Chen, K.: "Study on digital design platform for jaw crusher development ...

More

Types of Crushers Explained: Everything You Need to Know - JXSC

2024年4月19日 Jaw Crusher: Uses a reciprocating jaw to compress and crush material against a stationary plate: Primary crushing stage, handles large, abrasive materials: Up to 1,500 mm: 50-300 mm: Moderate to high: Simple design, reliable, handles abrasive materials: Limited reduction ratio, lower capacity compared to gyratory crushers: Cone Crusher

More

Industrial Solutions Jaw crushers - ThyssenKrupp

Single-toggle jaw crushers – design and operating principle Technical data Single-toggle jaw crusher Design Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate.

More

A fundamental model of an industrial-scale jaw crusher

2017年5月1日 There are two main types of jaw crushers, single toggle and double toggle. The difference being the resulting motion of the jaw depending on the design (Wills and Napier-Munn, 2015). Jaw crushers have proven to be a workhorse in the aggregates industry and are machines that reduce the top size but do not create fines or cubical particles to the ...

More

Understanding Types of Jaw Crusher: A Comprehensive Guide

Picture this: in a single toggle jaw crusher, the main engine shaft is installed at the very top. Now, the swing jaw hangs on this shaft, leading to some fancy jaw movement that’s a bit more complex than what you’d find in double toggle crushers. As the swing jaw dances up and down, its path looks like an ellipse.

More

What Are Jaw Crushers and How Do They Work? - Oreflow

The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary applications for using jaw crushers are: Crushing different kinds of ore; Reducing building rubble to pieces

More

Jaw Crusher Price Guide: Everything Buyers Need - JXSC

2024年4月25日 Size and Capacity: The size and the capacity of jaw crusher have a considerable effect on the price of the crusher. A small jaw crusher having a 250x400mm feed opening and a capacity of 5-20 tons per hour will cost less than a large jaw crusher with a 1,200×1,500mm feed opening and a capacity of 400-800 tons per hour.

More

Free CAD Designs, Files 3D Models The GrabCAD Community

The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

More- machines minières aurifères

- equipement de concassage de pierre en côte d'ivoire à vendre

- presse chaux machine à écraser le raisin

- portable concasseur de minerai d or à vendre angola

- fabricant de broyeurs à cône de dolomite portable algerie

- concasseur pour les chercheurs d or

- comment moudre outils de coupe de tour

- petite échelle concasseur de roche pour l or à vendre

- broyeur mobile tph avec ecran vibro

- sable brique faisant la machine ds

- concasseur à mâchoire Alibaba

- fabricants de concasseurs Gravier en Inde

- broyeur de mâchoire de moteur diesel de pec actif pour la pierre

- blast furnace slag crusher

- aluminium Ores Crushers machine de broyage de poissons

- comment faire de lart de cuivre