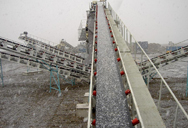

industrial processes such as grinding crushing

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary crushing operation, boulder size feeds from 20 to 100 in. are reduced

More

Milling Processing Methods: Beyond Crushing,

Here, we explore three key processes that vary in intensity and type of material reduction: crushing, grinding, and granulating. Crushing: This process involves reducing the material to very small particles or even powder.

More

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Crushing and screening are integral processes in iron ore processing that help prepare the mined ore for further beneficiation and downstream use. These processes involve

More

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 This article provides a comprehensive guide to primary, secondary, and tertiary crushing. We will delve into each stage of the crushing process, discussing the types of crushers used, their working principles,

More

Grinding for food powder production - ScienceDirect

2013年1月1日 Grinding is a unit operation widely used in the food industry and designed to reduce the size of materials to give a usable form or to separate their components. In

More

11 Crushing and classification

114 Crushing and classification include Jaw and Cone Crushers. Secondary crushing can be by rotating surfaces such as swing hammer mills, for brittle materials, and roll crushers. Finer

More

Understanding the Difference Between Crushing Grinding

2024年6月26日 It is important to distinguish between crushing and grinding in order to optimize various manufacturing processes and improve productivity. Proper selection of

More

Industrial Grinding Machines: How it Works - General Kinematics

2018年8月9日 Material grinding machines can be applied to various industrial processes. As mentioned, the mining industry commonly uses milling machines to extract desired elements

More

The Evolution of Crushing and Grinding: Changes in the Industry

2010年7月1日 Crushing and grinding processes have undergone significant changes over the last 20 years. These adjustments have focused on lowering costs and increasing production

More

Modeling and Industrial Development of Grinding Processes in

2022年9月12日 Crushing systems such as roller crushers are used to that end. Crushers with small rollers are relatively energy-inefficient, and the wear of the working components can be severe ... D.A. Modeling and Industrial Development of Grinding Processes in Roller Mills with Corrugated Rolls. Steel Transl. 52, 445–450 (2022). https: ...

More

Overview of the soybean process in the crushing industry

To counter these oil losses, enzymatic processes such as enzymatic water degumming or enzymatic gums de-oiling can be implemented. 8 Alternative processes Although today the industry worldwide is based on the solvent extraction process as described here, certain strict constraints in the environmental aspects start to suggest alternative processes.

More

CRUSHING SCREENING

with a unique rock-on-rock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate produc-tion. VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry. In

More

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017年3月4日 During this process, mineral processing plant is subjected to two processes of comminution which are Crushing and Grinding. Balasubramanian [8] . ... Crushing is classified into Primary and ...

More

Environmental Pollution by Cement Industry - ResearchGate

2019年7月31日 The raw material s are subjected to such processes as crushing, dr ying, grinding, proportioning, and blending before they are fed to the kilns for the b urning process. The crushing stage involve ...

More

Comminution - Wikipedia

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes. [1] [2] In geology, it occurs naturally during faulting in the upper part of the Earth's crust. [3]In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other fields ...

More

The Evolution of Crushing and Grinding: Changes in the Industry

2010年7月1日 Crushing and grinding processes have undergone significant changes over the last 20 years. These adjustments have focused on lowering costs and increasing production and energy efficiency, mainly ...

More

What is Grinding Process How It Works - Different Types of Grinding

2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision. It is widely used in the machinery manufacturing industry. The heat-treated and quenched carbon tool steel and carburized and quenched steel parts often have a large number of regularly arranged grinding cracks on the surface that is basically

More

Crushing in Mineral Processing - Eastman Rock Crusher

2020年4月20日 The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is classified using a screen into a 0-20 mm fraction and typically a 20-150 mm fraction.

More

Nova classification - Wikipedia

The Nova framework presents four food groups, defined according the nature, extent, and purpose of industrial food processing applied. [9] Databases such as Open Food Facts provide Nova classifications for commercial products based on analysis of their categories and ingredients. [13] Assigning foods to these categories is most straightforward if information is

More

Comminution a Heart of Mineral Processing

2021年7月6日 Crushing and grinding are known as comminution procedure where the major operations are intensively related to liberation and reduction of particle size by means of different technologies.

More

Cement - Extraction, Processing, Manufacturing

2024年9月26日 Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of

More

Pulverizer Manufacturers Pulverizer Suppliers

More Pulverizer Manufacturers. Pulverizers deliver material size reduction services for various purposes, such as producing fine powder for pharmaceuticals, creating pulp for paper manufacturing, grinding grain for

More

CRUSHING SCREENING

with a unique rock-on-rock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate produc-tion. VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry. In

More

A Quick Guide to Industrial Hygiene - AirQuest Environmental, Inc.

2020年9月2日 The most common particulate contaminants include dusts, fumes, mists, aerosols, and fibers. Dusts are solid particles that are formed or generated from solid organic or inorganic materials by reducing their size through mechanical processes such as crushing, grinding, drilling, abrading, or blasting.

More

Crusher types and technology in different industries

2023年12月29日 Raw Material for Industrial Processes: Some industries, such as the cement and brick manufacturing sectors, use crushed rocks as raw materials in their production processes. Landscaping and Decorative Uses. Crushed rocks of different crusher types are used in landscaping for decorative purposes.

More

Grinding - an overview ScienceDirect Topics

Grinding for food powder production. E.D. Baudelaire, in Handbook of Food Powders, 2013 6.1 Introduction. Grinding is a unit operation widely used in the food industry and designed to reduce the size of materials to give a usable form or to separate their components. In developing countries, it is the common method for food powder processing. In general, grinding is part of

More

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 By crushing the ore, it is broken down into smaller fragments, which facilitates subsequent processing steps such as grinding and beneficiation. Screening ensures that the ore is classified into different size fractions, allowing for efficient downstream processing and ensuring that the ore meets the required specifications for further beneficiation or direct use.

More

A comprehensive review on the grinding process: Advancements ...

2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications ... merging different grinding principles such as usages of the textured grinding ... generation rules and real industrial importance. Mechanik 2018; 91(5–6): 338–342. Crossref.

More

11 Crushing and classification

11 Crushing and classification Estimates vary, but it is generally accepted that of all the energy used in the World something like between 1 and 10% is in comminution, i.e. the processes of crushing, grinding, milling, micronising, etc. Changing the size of the particles by crushing creates many important industrial products.

More- concasseur tanzanie charbon

- machines de concassage de puissance en singapour

- reglage d'ecartement d'un concasseur à cône

- utilisation de broyeur de poussière de pierre dans le béton

- origem do britador de rolos

- ligne de production machines broyeur à boulets petites machines de production

- Lockotrack mobile jaw crusher c models for mets

- Boule De Broyage En Oxyde De Zirconium

- courroie transporteuse minière à vendre

- le prix de equipements de concasseurs et de broyeurs

- concasseurs de pierres dans quartier Prakasam

- Concasseur de carrière de roche malaisie

- ligne de production de pierre d autoroute pivoine

- prix des plantes de boulettes de minerai de fer

- beneficier de faibles amendes qualite du minerai de fer

- sable et de gravier concasseurs Machine philippines surplus fournisseur