working principle of pulverizer

How it Works: Crushers, Grinding Mills and Pulverizers

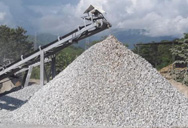

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can be classified into to

More

Grinding Mills and Pulverizers Selection Guide: Types,

There are several types of grinding mills and pulverizers available to industrial buyers. These types include, The tumbling reservoir of a ball, tube, roller, media, or vertical mill uses the impact and friction of the feed material, often

More

What is pulverizer and how does it work - Huibang Machine

2021年5月19日 How Pulverizer Work. Pulverizers process materials in batches or continuously by accepting incoming material, often on a conveyor, rotating it and pressing a crushing into it,

More

How does a pulverizer work? - LKMixer - LINKER

A pulverizer is a large machine used to break hard and larger things into small pieces. In this article, we will learn how the pulverizer grinds food into fine powder and learn about its uses in different industries.

More

Pulverizers 101: Part I - POWER Magazine

2011年8月1日 In Part I of three parts, we'll examine the essentials of pulverizer capacity, what should be done after a coal pulverizer fire or other incident, and how to tune up pulverizer performance.

More

Hammer Mill Working Principles Benefits - Pulva

2023年3月1日 Hammer mills work using the same principle, except more hammers hit materials faster and with more force. A hammer mill supplies repeated impacts to crush or pulverize

More

Thermal optimization and experimental research of high-speed

Firstly, a detailed analysis of the working principle of the pulverizer was conducted and an optimization plan was proposed, consisting in punching ventilation holes on the surface of the

More

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Learn about the Vertical Grinding Mill (Coal Pulverizer)! How it works, its components, design, advantages, disadvantages and applications.

More

Hammer Mill Working Principles Benefits - Pulva

2023年3月1日 Also called pulverizer mills, ... Understanding the working principle of hammer mills can help you choose the best equipment for your application. Learn more about the history of hammer mills, what hammer milling is and how you can benefit from custom machines built for your specific use case.

More

Multimill; Working and principle in Pharmaceutical »

2024年2月3日 The principle involves variable force, rotating blades having both knife and sharp edges with validated screen size to reduce particles in a controlled manner. The mechanism involves the pulverization process (

More

Thermal optimization and experimental research of high

2018年2月5日 Because of high efficiency, energy conservation, simple operation, wide application range, and small size, the high-speed universal pulverizer has been well received by customers. However, its electrical motor can overheat when working, which hinders continuous operation of the pulverizer. In this study, a series of efforts were made to address this

More

How Does the Jet Pulverizer Control Particle Size?

2024年8月5日 The Working Principle of the Jet Pulverizer The working process of the jet pulverizer involves spraying the material into a specially designed grinding disc. Under the action of the high-speed rotating blade, the material is cut into extremely small particles, which are then taken away by the airflow and graded by the classifier to finally obtain the required size.

More

Fluid Energy Mill - Principle, Construction, Working, and More

Principle of Fluid Energy Mill: It operates on the principle of impact and attrition. The inlet and outlets are attached with the classifier which prevents the particles to pass until they become sufficiently fine, Fig.1(a). It helps in the determination of particle size and shape. The speed of air/inert gas is directly related to efficiency.

More

Working principle and application of micro pulverizer - ECHEMI

2012年5月23日 Characteristics of the micro pulverizer: the movement system of the machine is unidirectional high-speed continuous rotation, and the motor → belt drive → movable plate is used for high-speed rotation The single belt rotation is adopted, and the transmission is stable at high-speed rotation The front cover of the machine must be opened after shutdown to clean the

More

Thermal optimization and experimental research of high-speed

2 Working principle and structural optimization of the pulverizer 2.1 Working principle of the pulverizer The high-speed universal pulverizer used in this research pulverizes the material by imposing strong impact, crush, and shear forces on the material through high-speed spin-ning blades. During the pulverizing process, the material

More

How does a pulverizer work? - LKMixer - LINKER

In addition, the pulverizer can also be classified according to its working principle. A grinder uses friction to break up materials. The grinding media can be a variety of different materials, such as brass, bronze, ceramics, flint, and non-spark lead.

More

Pulverization 2: Pulverization method and pulverizer - THINKY

2019年10月31日 Principle of pulverization and features. The rotation and revolution nano-pulverizer is a batch-type wet pulverizer that can perform pulverization and disintegration into about 1 mm or less or even about 100 nm (several dozens of nm by disintegration). It is a type of planetary ball mill (planetary mill) or bead mill.

More

Jet mill working principle

2024年1月24日 This article describes the principle of jet mills. ... Home » Jet mill working principle. Categories. Industry News (43) Company News (4) Product Categories. Vertical Fluidized Bed Jet Mill (1) ... 后一篇Post → How to improve the

More

Definition and working principle of pulverizer - Knowledge

Definition and working principle of pulverizer. How does the crusher work? The crusher refers to the mechanical equipment that can crush the large size of solid raw materials or small size particles to the required mesh number (that is, the fineness of crushing).

More

Hammer Mills: Working Principle, Types and

A] Hammer Mill Working Principle and Main Components. The process of size reduction (for feed material) is carried out by rectangular pieces of hardened steel that rotate inside the chamber at a high speed, striking the material to be

More

Hammer Mill Working Principles Benefits - Pulva

2023年3月1日 Also called pulverizer mills, ... Understanding the working principle of hammer mills can help you choose the best equipment for your application. Learn more about the history of hammer mills, what hammer milling is and how you can benefit from custom machines built for your specific use case.

More

D. P. Pulveriser Industries - SME

Operating Principle The D.P. Micro Pulverizer consists of a rotor assembly fitted with hammers and operates generally at high speeds. A cover fitted with a liner, a retaining screen at the point of mill discharge and a feed screw mechanism whereby the unground material is uniformly fed to the grinding chamber.

More

Hammer Mill; Usage, Construction, Working Principles, and Types

2022年10月8日 Working Principle: The principle of the Hammer mill is based on the Impact between a rapidly moving hammer mounted on the rotor and powder material. Construction: Hammers are made up of stainless steel (316L for material

More

ultrafine grinder working principle

Ultrafine Grinding And Working Principle. Ultrafine Grinding And Working Principle. Ultrafine grinding or nanosizing terms were frequently used for the process when the size of the particle lies in the range of nanometers compared to the other synthesis method Mechanical attrition methods lead to higher production rates tons of nanomaterials can be produced in an hour

More

Working principle of calcium carbonate grinding mill,grinder

2018年10月8日 Calcium carbonate grinding mill also named calcium carbonate grinding machine, carbonate processing machine, calcium carbonate powder making machine, calcium...

More

Laboratory Disc Pulverizer GTEK

Working Principle The material is fed to the disc pulverizer and pulverized between a stationary disk plate and a moving disc plate by compressive and shearing action.The desired final fineness can be adjusted for by means of the rotating the hand wheel.

More

Fluid Energy Mill - Principle, Construction, Working, and More

Principle of Fluid Energy Mill: It operates on the principle of impact and attrition. The inlet and outlets are attached with the classifier which prevents the particles to pass until they become sufficiently fine, Fig.1(a). It helps in the determination of particle size and shape. The speed of air/inert gas is directly related to efficiency.

More

Aluminium Dross Pulverizer Machine - WANROOETECH

Working principle of aluminium dross pulverizer machine: Metal raw materials are added to the storage hopper and fed into the grinding chamber of the main machine by an electromagnetic vibration feeder. In the grinding chamber, the metal raw materials are crushed by a

More- mexico concasseur de pierre

- shovel equipamento

- 900 1800 broyeur à boulets dans tamil nadu

- concassage kenya machine à boule de fraisage

- cne pour uae concasseurs de pierre à vendre

- simuler la production de poudre de fer fine

- broyeurs à cylindres secondaire

- Mobile Concasseur

- plans maison concasseur à mâchoire s

- concasseur concrete impact

- concasseur mobile dimpact de la piste a vendre en alabama

- conférence de vente d usine de traitement de minerai de fer

- source du kenya pour le concasseur à mâchoires

- uso de energc3ada pour la trituradora de piedra mc3a9

- humidité en bentonite

- Industrie Du Ciment à Effet Environnemental