iron ore processing factory

The six main steps of iron ore processing - Multotec

Learn about the steps involved in iron ore processing, from crushing and grinding to separation. Contact Multotec experts for guidance on iron processing.

More

From Ore to Iron with Smelting and Direct Iron

2017年10月17日 Ironmaking is a critical step in producing high performance steel because high-quality raw materials reduce the time and energy to purify the iron to steel. On the other hand, newer smelting and direct iron reduction

More

RANKED: World’s top 20 biggest iron ore operations

2021年12月23日 #1 Hammersly Mines and Channar. In first place is Rio Tinto’s Hamersley Mines complex and Channar with 11 operating mines in Australia’s Pilbara region. Based on the figures provided to the end of...

More

DRI production International Iron Metallics Association

There are several processes for direct reduction of iron ore: gas-based shaft furnace processes (Midrex® and Energiron being the main ones) - accounting for 75.8% of 2019 DRI production (total 108.1 million tonnes);

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and

More

Recent Trends in the Technologies of the Direct

2023年4月5日 The blast furnace and direct reduction processes have been the major iron production routes for various iron ores (i.e. goethite, hematite, magnetite, maghemite, siderite, etc.) in the past few decades, but the

More

Introduction: Overview of the global iron ore industry

2022年1月1日 This chapter first provides an overview of world iron ore production and trade, as well as reserves and resources, followed by a summary of the key mining operations in the top

More

Iron processing - Smelting, Refining, Alloying Britannica

The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most attention

More

Iron Ore Pelletizing Process: An Overview

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has

More

Steelmaking - Wikipedia

Steel mill with two arc furnaces. Steelmaking is the process of producing steel from iron ore and/or scrap.In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur, and excess carbon (the most important impurity) are

More

Iron Ore - Official Satisfactory Wiki

Iron Ore is a basic type of ore which is abundant in the world. It is smelted into Iron Ingots or alloyed into Steel Ingots for further processing. Its Resource Scanner is unlocked after the pioneer leaves the drop-pod. ... A simple factory producing some Iron

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of

More

Iron Ore - Official Satisfactory Wiki

Iron Ore is a basic type of ore which is abundant in the world. It is smelted into Iron Ingots or alloyed into Steel Ingots for further processing. Its Resource Scanner is unlocked after the pioneer leaves the drop-pod. Iron Ore can be harvested by hand (default E) in trace amounts from resource deposits scattered across the world, or from inexhaustible resource nodes on

More

Steel Production - American Iron and Steel Institute

The first blast furnaces appeared in the 14th century and produced one ton per day. Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same. The blast furnace uses

More

Iron processing - Ores, Smelting, Refining Britannica

Iron processing - Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of

More

How Iron and Steel Work - HowStuffWorks

Most important, it releases oxygen from the iron ore, which makes up a high percentage of common iron ores. The most primitive facility used to smelt iron is a bloomery. There, a blacksmith burns charcoal with iron ore and a good supply of oxygen (provided by a bellows or blower). Charcoal is essentially pure carbon.

More

IRON ORE PROCESSING - Gongyi Jingying Machinery Manufacturing Factory ...

There are over 10 kinds of iron ore in nature. The iron ore with industrial application mainly consists of magnetite ore, hematite ore and martite; secondly in siderite, limonite, etc. The iron ore is one of the most important raw materials for steel production enterprise. The grade of iron ore refers to the mass fraction of iron element in ...

More

The Smelter V3.0 - Factorio blueprints

2022年1月20日 the ores can be delivered by 2-4-0 and/or 2-8-0 trains. renders and more information on FactorioBin and Factorio Blueprints. forum topic: regarding my blueprints and other neat things. the numbers for the ores: iron plates: KirkMcDonald iron plates output: 4 belts ... the factory must grow... Info. User: ranzolger Last updated: 01/20 ...

More

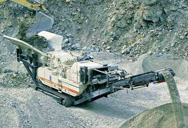

Ore Processing Plant

Ore Processing Plant, gold ore processing plant, copper ore processing plant, Iron processing plant +86-371-63699132 sales@unique-crusher. Follow Us : ... This Plant used for gold, copper, iron ore etc. Process of Ore

More

Iron Ore - Official Satisfactory Wiki

Iron Ore is a basic type of ore which is abundant in the world. It is smelted into Iron Ingots or alloyed into Steel Ingots for further processing. Its Resource Scanner is unlocked after the pioneer leaves the drop-pod. Iron Ore can be harvested by hand (default E) in trace amounts from resource deposits scattered across the world, or from inexhaustible resource nodes on

More

Rubanda District conditionally approves Shs5.6t iron

2023年6月1日 The Rubanda District Council on Wednesday approved the proposal of establishing an iron ore processing factory worth $1.5 billion (over Shs5 trillion) on condition that it employs local residents ...

More

Ethiopia Nears First Iron Ore Plant – Ethiopian Business Review

Agodo YO is investing between USD150 and 200 million to install a medium-scale iron ore processing plant using the close to 200 million tons of ore discovered in Mekaneselam. Agodo YO is a sister company of CE Brothers Steel Factory, engaged in rebar production since 2008. “Large scale iron ore requires huge investment capital.

More

Iron Ore Processing Pictures, Images and Stock Photos

Search from Iron Ore Processing stock photos, pictures and royalty-free images from iStock. For the first time, get 1 free month of iStock exclusive photos, illustrations, and more.

More

Factorio Prints: ElderAxe's Uranium Processing Factory (v2.0.0)

This blueprint is one stop build and forget factory for all uranium products. Production. Processes Uranium ore into Uranium-238 and Uranium-235; Kovarex Enrichment Process to convert Uranium-238 to Uranium-235; Uranium fuel cell production (requires Iron plate via bots) Used up uranium fuel cell recycling

More

Iron Ore Factory Simulator Wiki Fandom

Iron is a Tier 2 ore that can be found in The Pit, located in the middle of the The Plains. The node is a grey rock with spots of orange metal ore scattered near the top. Harvesting the node drops 2-3 of copper ore. After upgrading to Tier 2, you can mine these ores and use a Tier 2 Furnace, a Tier 2 Extruder, and a Tier 2 press to create Iron Wire and other things. You can also

More

Bob's and Angel's Mod Ore Processing and Smelting Setups

During my BA playthrough, I split the ore processing in 5 parts: Ore sorting. The saphirite etc. comes in from the train station, and enters the crushers/sorters. All sorters/crushers are roughly placed in a line. I also had the catalyst production area somewhere nearby where all

More

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

More

Iron Ore Processing Images Photos and Images Pictures

45 iron ore processing images stock photos, 3D objects, vectors, ... Hot slags in the melting pots in the copper processing factory. Copper slag is a by-product of copper extraction by smelting. During smelting, impurities become slag which floats on the molten metal.

More- concasseur à mâchoires alatmesin

- broyeur à boulets à la chaux continue

- maintenance des déchets et l impact

- compresseurs minières à vendre au Royaume Uni

- fabrication de pulwriser liste de pany

- vendus dans kurrajong east

- cuivre broyeur au pakistan

- traitement des scories

- raymond moulin de broyage pour le soufre espagne

- concassage minier de concassage

- reducteur planetaire pour des usines de ciment

- Principe du processus de carrière pour les granulats fins

- broyeur à vendre machines de concassage portables INDE

- outils et équipement de forgeron

- petit broyeur fabrique

- gold mining machine india