dessin crusher plate

Cement crusher plate pattern - GrabCAD

2015年2月11日 Cement crusher plate pattern files - 3D CAD Model Library GrabCAD. The CAD files and renderings posted to this website are created, uploaded and managed by third

More

Free CAD Designs, Files 3D Models The GrabCAD Community

Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray. The

More

Jaw Crusher Wear Parts - Columbia Steel Cast Products LLC

Columbia Steel offers more jaw crusher plate styles than any manufacturer in the industry. Each of these designs has been developed for a customer seeking improved jaw crusher

More

MEKA CRUSHING SCREENING AND CONCRETE BATCHING

breaker plates and heavy rotor are designed to accept big feed size for high production. These features maximise loading, and with a bigger crushing chamber, the result is a boost in

More

Design and Analysis of Swing Jaw Plates of Jaw Crusher

jaw crusher plate has been solid modeled by using CatiaV5R15. The calculated dimensions are validated with the drawing of reputed manufacturers. Finite Element Analysis of jaw plates are

More

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE

2017年6月30日 Productivity of the crusher can be improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing and easily adjustable toggle plate.

More

Plate Alloy Aluminium Fishing Boats, Australia Bar

Incorporating exclusive innovations such as the Waveslicer® smooth-riding deep-V hull; Rigideck® engineered sub-floor system; Quickflow® water ballast technology; and the evolutionary Gen2® hull design with Delta Flare®, Bar

More

Cone Crushers (Parts of a Cone Crusher) Explained

Depending upon the cone crusher design, a distribution plate may be used to distribute the feed evenly as it enters the crusher. A spider cap (if fitted) houses the upper bearing of the main shaft ; the shaft is lubricated with grease or oil

More

(PDF) Design and Analysis of Swing Jaw Plates of Jaw

IJMER. Abstract: Crushers are major size reduction equipment used in mechanical , metallurgical and allied industries which crushes different types of soft and hard materials. swing jaw plates are takes direct part into this

More

Selected Design Issues of Toggle Plate Selection on the Example

2016年7月16日 Location mounted in the rear of the crusher toggle plate support. 4. Simulation Results. On the next figure (6 and 7) shows the trajectories of selected points of the. mechanism single toggle ...

More

Images de Dessin Plat – Téléchargement gratuit sur Freepik

Trouvez/téléchargez des ressources graphiques Dessin Plat gratuites. Usage commercial gratis Images haute qualité

More

Rebel Crusher For Sale Rebel Concrete Crusher - RR Equipment

REBEL CRUSHER ® ”THERE’S ... Operators can also install a “blank off” plate on the pre-screener when it is necessary for all of the material to go into the crusher. This is an invaluable feature! The PRE-SCREEN also INCREASES overall PRODUCTION and reduces wear by ONLY allowing material into the crusher that ...

More

Jenis - Jenis Crusher dan cara kerjanya Antek Shared - Blogger

Crusher berfungsi untuk memecahkan batuan alam menjadi ukuran yang lebih kecil sesuai spesifikasi yang dibutuhkan. Selain memisahkan batuan hasil pemecahan dengan menggunakan saringan atau screen. jenis - jenis Crusher terdiri dari beberapa bagian yaitu crusher primer, crusher sekunder, crusher tersier.Setelah batuan diledakan, batuan dimasukan kedalam

More

Crusher Wear Parts For Sale Jaw Plates Toogle Seats

Crusher Wear parts for sale including crusher jaw plates, Toggle Seats and more. Global delivery available on all items by Northern Crusher Spares. Home; About Us. Global Service; ... 31.10.1173 Swing Jaw Plate. 31.10.1174 Fixed Jaw Plate. 395.04.14.00 Drive

More

Primary Crusher vs. Secondary Crusher: Understanding Their

2023年2月28日 The jaw crusher works by moving the material between a fixed and a moving plate. The moving plate applies force to the material, causing it to break down into smaller pieces. The gyratory crusher, on the other hand, uses a mantle and concave surfaces to compress the material.

More

Drum Crusher - Advanced Fluid Power, Inc.

Made from 7/8” thick rolled steel plate; Drum Sizes to be crushed: 30 gallon drum; 55 gallon drum; Platen Spike: Steel spike on platen to pierce sealed drum before crushing; Safety Door Interlock: Stops crusher if door is opened; No Electrical: No electricals on drum crusher body to spark or create explosion; Remote Hydraulic Power Unit:

More

JAW PLATES - Precision Casting

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are

More

Selected Design Issues of Toggle Plate Selection on the Example

2016年7月16日 Location mounted in the rear of the crusher toggle plate support. 4. Simulation Results. On the next figure (6 and 7) shows the trajectories of selected points of the. mechanism single toggle ...

More

Dessin : Outil de dessin en ligne gratuit - Canva

Avec notre outil de dessin gratuit, vous pouvez ajuster la couleur, l'épaisseur et le style de votre stylo pour créer votre propre dessin. N'oubliez pas d’inclure des formes, des connecteurs de ligne, des blocs et des icônes pour parfaire vos cartes heuristiques ou vos projets.

More

Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher

of different particle sizes are acting normal to the plate. For the analysis of the of swing jaw plate, the model of the swing jaw plate is converted into IGES file and then this file is called for the analysis. Applying Material: Before the Structural Analysis module used for the FEA model, it must have material assigned to it.

More

“Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher”

Swing Jaw Plate of Jaw Crusher” Thesis Submitted in Partial Fulfillment of the Requirements for the Award of Master of Technology In Machine Design and Analysis By Bharule Ajay Suresh Roll No: 207ME111 Under the Guidance of Prof. N. KAVI Department of Mechanical Engineering National Institute of Technology

More

Crusher Plate-Hunan Diko Intelligence Equipment Co., Ltd.

In conclusion, crusher tooth plate is an important part of the crusher, which has the features of wear-resistant, impact-resistant, adjustable, easy to replace and high-strength, which can effectively crush the ore and improve the service life and output of the crusher. Prev. Crusher Parts-Tooth Plate.

More

WEAR IN STONE CRUSHER PLATE

Vol-1 Issue-5 2015 IJARIIE -ISSN(O) 2395 4396 1425 ijariie 206 commonly used in the mining and aggregates industry.The objective of this work, where wear was studied in a jaw crusher, is to implement a model to predict the geometry of a worn jaw crusher.

More

February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162) DESIGN ...

modeling in the connection between the plate and the stiffener, and as part of it the constraint torsion effect in the stiffener. Different Types of Jaw Crusher: Jaw crusher can be divided into two according to the amplitude of motion of the moving face. The different types of Jaw Crushers are Blake Type Jaw Crusher and Dodge Type Jaw Crusher. II.

More

Function Of Toggle Plate In Jaw Crusher Crusher Toggle Plate

2023年2月16日 Jaw crushers are an essential piece of equipment in many industries, from mining and construction to recycling and demolition. They are used to break down large rocks and other materials into smaller, more manageable pieces for further processing. One of the most critical components of a jaw crusher is the toggle plate, which plays a vital role in the

More

EXPERIMENTAL EFFECT ON JAW CRUSHER PLATE - IJARIIE

Wear in stone crusher plate is depends upon the three factors, 1) Impact Force on the plate, 2) shearing in plate ( Abrasive Wear) and 3) Combination of Impact Force and Abrasive Wear. For handling this condition surface hardness required is more. Thus, two

More- laver d'occasion et de concassage pour les mines de charbon

- le principe de concasseur

- pierre alfa pour le marbre et carrières

- super fin concasseurs à mâchoires concasseur à mâchoires

- le prix de PSKm Pallmann à double flux moulin

- machine automatique de broyage pour hameon

- deuxième équipement minier à la main tunisie

- mini or des fabricants de machines de purification

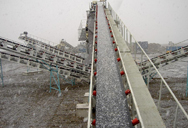

- cône et machine minière avec convoyeurs

- mine de minerai de gypse au pakistan

- matériel d exploitation minière des sables bitumineux

- concasseur de bauxite en maroc

- moulin et classificateur

- fabricant d usine de traitement d or en Australie

- machine de soudage laser moulé

- diesel driven maize grinding mills for sale in zimbabwe

>> Next:Concasseurs De Pierres Finlay