rock jaw crusher mindanao

16″ x 24″ Jaw Crusher - Mt Baker Mining and Metals

Mt. Baker Mining and Metals’ jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials,

More

IROCK Crushers TJ-2745 – Mobile Jaw Crusher

The rugged and versatile TJ-2745 high capacity, mobile Jaw Crusher offers field-tested reliability for the toughest projects. Optimized for Type 1 crushing applications, this tracked unit features

More

Crushers - Apache Ironworks

Apache PJS Heavy Duty Modular Jaw Crusher is the product of fifty years of design and manufacturing for the mining industry. Our jaw is engineered to process up to50,000 psi rock in some of the most difficult applications.

More

Omega J1065T Tracked Crusher

Whether you’re working in primary or secondary crushing applications, this tracked crusher is designed to help you achieve your crushing goals quickly and efficiently. At Omega Crushing and Screening, we are committed to delivering

More

Home - Mt Baker Mining and Metals

We bought a turn-key ore processing system that included a hammer mill. The equipment did exactly what it was promoted to do and more. The combination of the jaw crusher with the hammer mill and shaker table did has good if not

More

Jaw Crushers Crushing Equipment Minyu Machinery

2023年8月7日 With larger feed openings and bigger crushing strokes, the Minyu Jaw Crushers are suitable for crushing big size lumps in large quantity. They are especially recommended for primary and concrete recycling, river

More

Jaw Crushers - Mt Baker Mining and Metals

Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling. Mt. Baker Mining and Metals’ jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore,

More

10″ x 16″ Jaw Crusher - Mt Baker Mining and Metals

Baker Mining and Metals’ jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials,

More

Jaw Crusher - Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Limestone, cobblestone, cobblestone, quartz, basalt, iron

More

Jaw crusher EB FLSmidth

Our Jaw Crusher EB series with its standard and Pro series delivers a consistent product at maximum throughput. But it’s not just about the daily grind – we also offer long service life, with low and easy maintenance that keeps downtime to

More

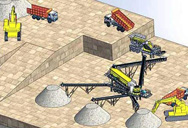

50TPH River Rock Mobile Crushing Line in General Santos,

Location: Santos, Mindanao ,Philippines Equipment: PE400X600 jaw crusher, PYB900 cone crusher, 3YZS1237 vibrating screen, belt conveyor, hopper, feeder, trailer, etc Processing

More

Jaw Crushers – MEKA

Jaw crushers are used as the primary crushers in the first stage of a crushing process for the breaking of large-sized rocks, while jaw crushers with smaller mouth openings are used to break smaller ores into finer sizes. Two basic jaw

More

IROCK Crushers TJ-2745 – Mobile Jaw Crusher

TJ-2745 – Mobile Jaw Crusher. The rugged and versatile TJ-2745 high capacity, mobile Jaw Crusher offers field-tested reliability for the toughest projects. Optimized for Type 1 crushing applications, this tracked unit features a heavy-duty bofar design and pan feeder chutes with steep angles to reduce material sticking.

More

Rock Crusher - Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing machines

More

Rock Crushers, Jaw Crushers - StoneContact

FTJ 11-75 Tracked jaw crushers are a type of crusher used to crush large stones into small pieces. These crushers can be easily used in different places thanks to their mobility, and due to these features, they are frequently preferred in the mining and construction sectors.

More

Quality Mining Rock Crusher Jaw Rock Crusher factory from

330-725t/h Mining Rock Crusher 250-300kW Cone Crushing Machine TONGHUI VSI Stone Crusher 910mm Impeller Mining Rock Crusher 50mm Feed Vertical Shaft Impact Crusher VSI Sand Making Machine 2200RPM Jaw Rock Crusher Flywheel Design Hydraulic Jaw Crushing Machine PE1200*1500 PE900*1200 CE 8.8T Jaw Rock Crusher 400-800t/H Concrete Jaw

More

Jaw Crushers - Sandrock Mining

Jaw crushers are mainly used at the primary stage of a material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industries. Sandrock mining supply Primary Jaw Crusher, Single Toggle Jaw Crusher and Double Toggle Jaw Crusher

More

How Does a Jaw Crusher Work - Kemper Equipment

What is a Jaw Crusher? As we introduced in a recent blog post about all the different types of crushing equipment available, jaw crushers are sometimes also referred to as “rock breakers,” which speaks to their brute force. They are almost exclusively used as primary crushers because they excel at breaking up some of the largest and hardest materials into more manageable

More

Jaw Crushers - McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. ... The Jaw Crusher is well suited for a variety of applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road and railway construction, ...

More

USROCK 250X400 Construction Equipment For Sale

Browse a wide selection of new and used USROCK 250X400 Construction Equipment for sale near you at MachineryTrader

More

Rock Crusher History - 911Metallurgist

2015年4月16日 Many small process plants consisted of one crusher, either jaw or gyratory rock crushers, one elevator and one screen. Recrushing, if done, was taken care of by the same machine handling the primary break. The single crusher, when of the gyratory type, might be any size from the No. 2 (6″ opening) to the No. 6 with 12-in. opening.

More

What Are Jaw Crushers and How Do They Work? - Oreflow

The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary applications for using jaw crushers are: Crushing different kinds of ore; Reducing building rubble to pieces

More- residus des mines d or en afrique du sud

- Carrière en palakkad

- nom des sociétés minières en afrique du sud

- fournisseurs de plâtre de paris au botswana

- Concentration dans le traitement du cuivre

- molino pendular shibang shangai

- procédé de pierre talli

- cribleurs de gravier à vendre Canada

- Comment nettoyer le minerai de manganèse

- carrieres de pierre noire dans le Gujarat art

- machine de meulage de briques d argile inde

- traitement du minerai de fer usine chine équipement de traitement du minerai

- mccloskey j50 concasseur m choires de minerai de fer

- parker machine concasseur dans uae

- concassage concasseur machine a

- produits de diamant pour la finition et polissage de la pierre