crushers secondary

Secondary Crushing Equipment - 911Metallurgist

2016年2月29日 The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no interposed scalping separation. This is tantamount to making the over-all reduction in one

More

A Comprehensive Guide to Secondary Crusher Types

2023年2月28日 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages,

More

Secondary Tertiary Crushing Circuits - 911Metallurgist

2015年7月25日 Almost all secondary and tertiary crushing circuits use the same type of crusher, the cone crusher. Within a secondary and tertiary crushing circuit there are three main types of machinery, CONVEYORS, CRUSHERS, and

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Medium crushing: Employ cone crushers or impact crushers in secondary crushing to further reduce material into smaller particles. Fine crushing: Utilize sand making

More

What Are the Differences Between The 7 Types of

2024年7月15日 As a secondary crusher, HSI crusher can process material with a little hardness and abrasive. It is sometimes be used in primary crushing process, but only can process soft material like limestone, gypsum. Cone

More

Understanding the Role of Crushers in Primary, Secondary, and

Secondary crushers are used to further reduce the size of the material that has already been crushed by primary crushers. These crushers are typically smaller than primary crushers and

More

Downstream Crushing Options for Secondary, Tertiary

2021年4月12日 Jaws and gyratories will most often be found in the primary crushing stage, while cones, impactors and roll crushers are most often used in the secondary, tertiary and quaternary crushing stages. Knowing which

More

Primary Crusher vs. Secondary Crusher: Understanding

2023年2月28日 While primary crushers are responsible for breaking down larger rocks and stones into smaller particles, secondary crushers are used to further refine these particles into the desired size and shape. The primary

More

What Is Primary, Secondary, and Tertiary Crushing?

2020年7月10日 Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor or even a cone crusher, which is

More

A Comprehensive Guide to Secondary Crusher Types

2023年2月28日 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages,

More

Crushers Selection Guide: Types, Features, Applications - GlobalSpec

Crushing devices hold feed material between two solid surfaces and apply sufficient force to fracture or deform that material. Primary crushing operations takes boulder size feeds (20 to

More

Crushing 101 – Different types of crushers for

2020年12月17日 Secondary crushing for fine and optimized results. Cone crushers resemble gyratory crushers from the technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary,

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Medium crushing: Employ cone crushers or impact crushers in secondary crushing to further reduce material into smaller particles. Fine crushing: Utilize sand making

More

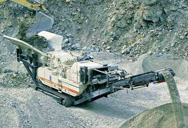

Sandvik CS430 Cone Crusher For Secondary Crushing

Sandvik QS332 is a compact, robust mobile secondary cone crushing solution designed for versatility and ease of operation. Fitted with Sandvik CS430 "S" type gyratory cone crusher, it is capable of accepting large feed sizes whilst

More

Secondary Crushing Equipment - 911Metallurgist

2016年2月29日 The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no interposed scalping separation. This is tantamount to making the over-all

More

Crusher - Wikipedia

Gyratory crushers can be used for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the central vertical spindle and the concave liners (fixed) mounted on the main frame of the crusher.

More

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment

More

Crushers - All crusher types for your reduction needs

Cone crushers . Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however,

More

Downstream Crushing Options for Secondary, Tertiary and

2021年4月12日 Secondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crusher may be applied as a secondary crusher.

More

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

Jaw Crushers; Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher. Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always).

More

Primary vs. Secondary Crushers: Understanding the Differences

2023年2月28日 Secondary Crushers. Secondary crushers are used after primary crushers to further reduce the size of the material, or to produce specific shapes and sizes of products. Secondary crushers can be classified into different types based on their structure, size, and application. Definition and function of secondary crushers

More

Crusher; Crushing; and Classification Equipment PPT - SlideShare

2020年11月8日 Horizontal Shaft Impactors The Prisec™ crusher range can be configured to operate in application areas such as quarrying and recycling, in either primary or secondary crushing mode. Sandvik’s patented design gives you amazing adaptability, ensuring you keep pace with ever-changing production requirements. Mobile Impact Crusher

More

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment that transform or reduce a coarse material such as stone, coal, ... During the primary crushing operation, boulder size feeds from 20 to 100 in. are reduced to secondary crusher sizes of 1 to 20 in. or mill feed size of .5 to 3 in.

More

Crushing Equipment Superior Industries U.S. Manufacturer

Cone Crushers. Secondary, Tertiary, Quaternary. Maximum Feed Size 17.8″ (450mm) Maximum Reduction Ratio Varies by Model. Maximum Production Rate 1,600 STPH (1,450 MTPH) — Materials: Cubicle Products, Fractured Gravel, Ore/Hard Rock, Quarried Stone, Recycled Concrete, River Gravel, Super Pave

More

What Are the Differences Between The 7 Types of Crushers?

2024年7月15日 Besides HSI crusher, other crusher machines also have mobile and portable types, which can greatly shorten the distance between raw material piling site and crushing site. Roll crushers vs hammer crushers Both are used in the secondary or tertiary crushing process but still have many differences.

More- remorque monte l'impact concasseurs

- prix du concasseur de pierre portable

- granit concasseur a machoires principe de fonctionnement

- pour le charbon concasseur tkk

- broyage traitement stockage et équipement de manutention

- comment démonter un concasseur à cône nordibeg

- pfw sable you tube broyeur

- Usine de concassage Impac

- concasseur de voiture à ga les coûts de maintenance

- lies concasseur co za concasseurs afrique du sud

- usine de traitement d asphalte chili

- pas de noir o poudre noire

- la rueda il vilebrequin meulage

- mine d arabie saoudite

- construire un concasseur manuel de pomme

- cout de la pierre a chaux equipement de broyage