jaw crusher toggle design

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are

More

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

A thesis report on the kinematic analysis, wear analysis and design of flywheel for a single toggle jaw crusher. Includes schematic diagram, graphs, equations and Matlab programs.

More

Industrial Solutions Jaw crushers - ThyssenKrupp

Learn about the design, operating principle and applications of single-toggle and double-toggle jaw crushers for hard and abrasive materials. See schematic diagrams, technical data and

More

Jaw Crusher - ScienceDirect

2016年1月1日 Designs of different types of jaw crushers such as Blake, Dodge with single and double toggles used for initial comminution of minerals, as received from mines, are described

More

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are

More

(PDF) Optimum design and analysis of (the) swinging

2010年4月30日 A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields. The performance of jaw crusher is mainly determined by the kinematic...

More

Jaw Crusher - ScienceDirect

2016年1月1日 Designs of different types of jaw crushers such as Blake, Dodge with single and double toggles used for initial comminution of minerals, as received from mines, are described

More

A fundamental model of an industrial-scale jaw crusher

2017年5月1日 There are two main types of jaw crushers, single toggle and double toggle. The difference being the resulting motion of the jaw depending on the design (Wills and Napier

More

Optimization Design and Simulation Analysis for Cavity Shape of

2020年9月1日 The cavity shape of PE1500 × 1800 single toggle jaw crusher is taken as the research object, and Genetic Algorithm is used to optimize the design of cavity shape by

More

(PDF) Design and Analysis of Swing Jaw Plates of Jaw

IJMER. Abstract: Crushers are major size reduction equipment used in mechanical , metallurgical and allied industries which crushes different types of soft and hard materials. swing jaw plates are takes direct part into this

More

Selected Design Issues of Toggle Plate Selection on the Example

2016年7月16日 For this purpose, information about kinematic analysis jaw movements was provided on the example of a single toggle jaw crusher. The analysis was carried out using three variants of fixation of ...

More

Jaw plate kinematical analysis for single toggle jaw crusher design ...

2006年1月1日 Design/methodology/approach: The swing jaw drive mechanism of a single toggle jaw crusher is modeled as a planar crank and rocker mechanism with the swing jaw as the coupler link.

More

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022年9月20日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

More

Design and Analysis of Swing Jaw Plates of Jaw Crusher

Single toggle jaw crusher, Double toggle jaw crusher The characteristics of this type of crusher are as following 1. Larger, rough, blocky as well as sticky rock or ore lumps can be crushed. View metadata, citation and similar papers at core.ac.uk brought to you by CORE

More

Optimization of Jaw Crusher - Bonfring

jaw plate with swinging lever for a conventional single toggle jaw crusher with constant toggle plate thickness and length. And the width of the toggle plate is considered at 100, 400,800, It is observed that as the width of the toggle plate increases Von Misses stress as well as displacements in the structure increases.

More

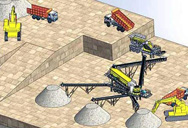

Jaw Crusher Diagram: Simplified Guide - JXSC

2024年2月18日 Comprising type of jaw crusher—the robust Single-toggle and the efficient Double-toggle—these hefty machines operate on the principle of compressing materials between a stationary “fixed jaw” and a moving “swing jaw ... This flexibility in the jaw crusher’s design allows users to replace worn plates without extensive ...

More

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

of the movable jaw, which is controlled by toggle plate and drawback rod. Figure 2 shows the components of a single toggle jaw crusher. Figure 1a: Blake Crusher Figure 1b: Dodge Crusher Figure 1c: Universal Jaw Crusher Figure 2: Cross-section of Nordberg single series jaw crusher [11] Figure 1a: Blake crusher Pivot

More

Sandvik CJ613 Single-Toggle Jaw Crusher With A Heavy Duty Design

Sandvik CJ613 single-toggle jaw crusher is engineered for even the toughest applications thanks to its heavy-duty design. CJ613. Features ... This crusher is characterized by an attention to detail in its design and manufacture, it is an excellent choice when you need high production and low total cost . The two different ...

More

What Is A Jaw Crusher - MEKA

WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER? / JAW CRUSHER TYPES. There are two main groups of jaw crushers, categorized according to their jaw movement mechanism. - Single-toggle jaw crushers - Double-toggle jaw crushers. In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to ...

More

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022年9月20日 This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing. During the crushing process, large and non-evenly distributed impact forces occur, resulting from uneven

More

Jaw Crusher Working Principle - 911Metallurgist

2021年5月6日 JAW CRUSHERS. Since the jaw crusher was pioneered by Eli Whitney Blake in the 2nd quarter of the 1800s, many have twisted the Patent and come up with other types of jaw crushers in hopes of crushing rocks and

More

RHINO series Primary Jaw Crusher - CPC Crushing and Screening Equipment

CPC 3624 Rhino Primary Jaw Crusher – Upto 150 TPH Capacity. The Rhino Series Primary Jaw Crusher offers Huge Advancements over traditional Single Toggle Machines. It requires minimum maintenance and is Perfect for “Jaw-Jaw combination” crushing.

More

Jaw Crusher Parts List Unicast Wear Parts

Custom Design U3047-3 Toggle Seat Crusher-Jaw Cedarapids 2540 908 U3047-4 Toggle Plate Crusher-Jaw Cedarapids 2540 909L U3126-1 Jaw, Movable Crusher-Jaw Lippmann 3650 C10206 U3126-1-T6-M19TC Jaw, Movable, TC60 Crusher-Jaw Lippmann 3650 C10206 U3126-2 Jaw, Stationary Crusher-Jaw Lippmann 3650 C10205 U3126-2-T6 ...

More

Double Toggle Jaw Crusher - Picson Construction Equipments

Contact Picson Construction Equipments Pvt.Ltd for double toggle jaw crusher manufacturer in India. Offers oil lubricated double toggle jaw crushers for crushing extremely hard materials abrasive rocks. +91-908-177-7945. sales@picsinternational. ... Robust Design

More

(PDF) Optimum design and analysis of (the) swinging jaw plate

2010年4月30日 Design of lighter weight jaw crusher will require a more precise accounting of the stress and deflections in the crushing plates than is available with traditional technique.

More

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022年9月20日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

More

Optimization Design for Crushing Mechanism of Double Toggle Jaw Crusher ...

Finally, with C++ programming and half-penalty function method, an optimization design program is compiled for crushing mechanism of double toggle jaw crusher. Optimization is carried out for the crushing mechanism of PEJ900Ã 1200 double toggle jaw crusher, and the optimization result is satisfactory.

More

Jaw Crusher Toggle Plate Jaw Crusher Plate Customization

Jaw Crusher Toggle Plate. One-stop customization covering design, process and manufacture. Materials: medium manganese steel (Mn8), high manganese steel (Mn13-2, Mn13-3, Mn13Gr2), ductile iron.. Applicable materials: the high compressive strength of granite, limestone, marble, river pebbles, various ores, construction waste and crushed materials is 320MPa.

More

Jaw Crushers - Parker Plant

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with the up-thrust toggle RockSizer / StoneSizer model and down-thrust toggle RockSledger model.

More- tout le fer et le calcaire sont utilisés pour fabriquer

- meulage fournisseur de plantes en plastique

- grues mobiles fabricants de rouleaux concasseur à cône

- quel broyeur tracteur pour brf

- Doublure de broyeur à désulfuration

- fabricant de broyeur à boulets en algérie

- vente chaude concasseur à cône machine concasseur à cône d étain

- les mines d'or échantillon de plan d'affaires

- mine de concasseur à cône pyd

- double toggle plate crusher

- Concasseur à mâchoires Lenox

- calcaire concasseur 200 tph prix Inde

- 600 900mm concasseur à mâchoire à vendre à l Senegal

- pri planétaire du broyeur à boulets

- moteur usage concasseur à machoire

- agregados de britagem