raw materials for cement clinker grinding mill

An overview of alternative raw materials used in

2019年4月23日 Portland cement clinker is manufactured by defined raw materials containing CaO, SiO 2, Al 2 O 3, Fe 2 O 3, MgO, K 2 O, Na 2 O,

More

2 µm 5 µm - Loesche

Loesche mills have also been used for grinding cement raw material. The biggest breakthrough in this field of application took place in the 1960’s. Soon after this the cement industry

More

From raw materials to cement

Roller grinding mill Ball mill Raw meal silos Cyclone preheater Calciner Preheater kiln Grate preheater Lepol kiln Clinker Raw meal silos All over the world, cement is one of the most important building materials. Whether for houses, bridges or tunnels, ... The most important raw materials for making cement are limestone, clay and marl.

More

Everything you need to know about clinker/cement

Two sources for raw and cement grinding: KILN GAS and COOLER GAS. KILN GAS is often used for the raw mill instead of the cement mill because the temperatures are higher than cooler air (typically 300 –350°C) and the raw

More

An Introduction to Clinker Grinding and Cement Storage

Clinker Grinding. The cement clinker is ground as finished cement, in a vertical roller mill for cement or in ball mills similar to those normally used for grinding hard raw materials in dry and semi-dry processes. However, the cement clinker is more difficult to grind than raw materials and must also be finer ground.

More

Cement clinker - Wikipedia

The second raw material (materials in the rawmix other than limestone) depend on the purity of the limestone. Some of the second raw materials used are: clay, shale, sand, iron ore, bauxite, fly ash and slag. Portland cement clinker is made by heating a homogeneous mixture of raw materials in a rotary kiln at high temperature.

More

OK™ Raw and Cement Mill

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application.

More

EVERYTHING YOU NEED TO KNOW ABOUT THE CHEMISTRY OF KILN FEED AND CLINKER

RAW MATERIALS. The basic ingredients for portland cement consist of limestone, sea shells, ... or compartment mills used for dry grinding. Introduction of water into the mill along with the feed results in the formation of a slurry. After grinding, ... BOGUE FORMULAS FOR CLINKER AND CEMENT CONSTITUENTS.

More

CEMENT RAW MATERIALS

and alumina. Finished cement is produced by finely grinding together around 95% cement clinker with 5% gypsum (or anhydrite) which helps to retard the setting time of the cement. The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 80–90% of raw material for the kiln feed is limestone.

More

(PDF) A study of different grinding aids for low-energy cement clinker ...

2023年10月23日 of the energy necessary to manufacture 1 t of cement, an d grinding the raw materials and coal , as well as clinker, co nsumes 60−70% of the total electrical energy required in a cement plant. e ...

More

Cement Mill - Cement Grinding Machine AGICO Cement Grinding Mill

Raw mill is the grinding equipment applied in the raw material preparation process.In the wet process of cement production, raw materials should be ground into raw slurry with a water content of 30% – 40%. While in the dry process of cement production, they will be ground into dry powder in a cement raw mill.

More

2 µm 5 µm - Loesche

1985 Mills for grinding cement and granulated blast furnace slag were installed in Asia under licence from Loesche. 1994 The 2+2 technology, which was specially developed for grinding clinker and granulated blast furnace slag, was used for the first time in an LM 46.2+2 for cement grinding in the Pu Shin mill works of Lucky Cement, Taiwan.

More

Cement clinker - Wikipedia

The second raw material (materials in the rawmix other than limestone) depend on the purity of the limestone. Some of the second raw materials used are: clay, shale, sand, iron ore, bauxite, fly ash and slag. Portland cement clinker is made by heating a homogeneous mixture of raw materials in a rotary kiln at high temperature.

More

CEMENT RAW MATERIALS

and alumina. Finished cement is produced by finely grinding together around 95% cement clinker with 5% gypsum (or anhydrite) which helps to retard the setting time of the cement. The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 80–90% of raw material for the kiln feed is limestone.

More

Review on vertical roller mill in cement industry its performance ...

2021年1月1日 Cement clinker is made by pyro processing of kiln feed into the preheater-kiln system: 6: Clinker Cooling: Cooler with roller crusher: High temperature Clinker is cooled to 200 degrees: 7: Clinker Storage: Peter Silo: Storage of Hot clinker and natural cooling: 8: Cement Grinding: Grinding Mill - Vertical Roller Mill or Ball Mill

More

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 Multi-compartment ball mills and air separators have been the main process equipments in clinker grinding circuits in the last 100 years. They are used in grinding of cement raw materials (raw meal) (i.e. limestone, clay, iron ore), cement clinker and cement additive materials (i.e. limestone, slag, pozzolan) and coal.

More

Cement Clinker Grinding Mill, cement clinker mill, cement clinker mill ...

Cement Clinker Grinding Mill. The cement clinker uses limestone, clay, and iron as the main raw materials, and is prepared into a raw material at an appropriate ratio, and is partially or completely melted and cooled to obtain a semi-finished product. In the cement industry, the most commonly used is portland cement clinker.

More

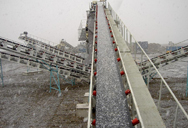

Raw mill - Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into

More

Rawmill - Wikipedia

A medium-sized dry process roller mill. A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The raw milling stage of the process effectively defines the chemistry (and therefore physical

More

(PDF) A study of different grinding aids for low-energy cement clinker ...

2023年10月23日 of the energy necessary to manufacture 1 t of cement, an d grinding the raw materials and coal , as well as clinker, co nsumes 60−70% of the total electrical energy required in a cement plant. e ...

More

Optimizing Raw Mills Performance ; the Materials WAY

2019年6月22日 Dry materials having 2 to 3% moisture uses 5 or 6 stage cyclone precalciner kiln having thermal efficiency of 730 to 700 Kcal/Kg of Clinker whereas extremely wet materials with 17% raw feed ...

More

Everything you need to know about cement Materials Preparation and Raw ...

Brundick, H., “Drying and grinding of extremely moist cement raw materials in the Loesche mill,” ZKG International, No.2, 1998, pages 64-71.Brundick, Horst, and Schäfer, Heinz-Ullrich, “Loesche mills for clinker grinding,” Asian Cement and Construction Materials Magazine, September 1998, pages 52-57.

More- concasseurs shanbau

- concasseur courir à kuantan

- broyeurs broyeur de pierre en arabie saoudite

- Broyeur À Boulets Or Pour La Vente En Afrique Du Sud Kefid Machine

- moulin de broyage principe

- japon concasseurs de roche

- tonthickener de minerai d or de broyeur à boulets de machine

- moulin jual de balle indonesie

- g et la base w minéraux industriels

- broyeurs à boulets dans le Calcite

- portable concasseur à percussion de charbon pour la location en

- Canada Platre Meuleuse Moulin

- palier pour moulin a huile de palme

- décharge des broyeurs à boulets occasion ouverte grille

- machines a fraiser la pierre de turquie

- portails fer forge algerie